Name: John Wu

Mobile: +86-18627194522

E-mail: sales@xintongsteel.com

Add: NO.16, XISAI INDUSTRIAL AREA, HUHANGSHI CITY, HUBEI PROVICE, CHINA

Skype: john.wu1605

MSN: john.wu1605@hotmail.com

|

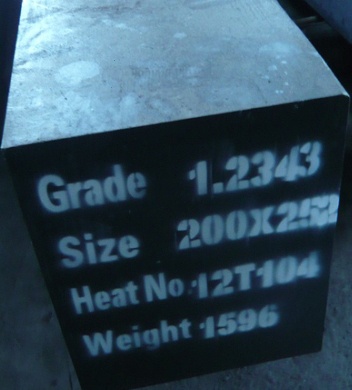

Product name : SKD6/1.2343/ H11Hot Work Tool Steel

Item : 20201027124856

|

| Details: | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Equivalent Grades of 1.2343 steel

Typical Chemical Composition (%)

Hot Forming Forging: 1100 to 900℃, slowing cooling in furnace. Heat Treatment of 1.2343/H11 steel Annealing: 750 to 800℃, slow cooling in furnace (10-20℃/hr), down to 600℃, cooling in air. Hardness after annealing: max. 230 HB. Stress relieving: 600 to 650℃, slow cooling in furnace. Hold in neutral atmosphere for 1 to 2hours. Hardening: 1000 to 1040℃, oil/air, hold 15 to 30 minutes. Hardness , 52 to 56 HRC in oil, 50 to 54 HRC in air. Tempering: 560 to 580℃. Slowly heating to tempering temperature right after hardening. Recommended to temper at least twice. The second tempering temperature shall be approx. 30℃ lower than the first tempering.

* Hardening temperature: 1020℃, specimen size: dia50mm

Surface treatment Nitriding: Suited for both bath and gas nitriding.

Properties of 1.2343/H11 steel High impact strength, excellent hot tensile properties and deep hardening properties, insensitivity to thermal shocks. Water cooling available.

Applications of 1.2343/H11 steel Heavy duty hot work tools and dies: mandrels, dies, and containers for metal tube and rod extrusion; hot extrusion equipment; tools and dies for the manufacture of hollow bodies, screws, rivets, nuts, and bolts. Die casting equipment, forming dies, die inserts, hot shear blades, and plastic moulding dies.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Related Products : |

|

|

Alloy tool steel

Alloy tool steel