Name: John Wu

Mobile: +86-18627194522

E-mail: sales@xintongsteel.com

Add: NO.16, XISAI INDUSTRIAL AREA, HUHANGSHI CITY, HUBEI PROVICE, CHINA

Skype: john.wu1605

MSN: john.wu1605@hotmail.com

|

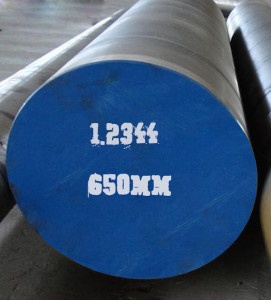

Product name : H13/1.2344/SKD61/4Cr5MoSiV1

Item : 20131012113653

|

| Details: | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Product Details Chemical Composition (%)

Specification

Heat Treatment

Quenching technique

Forging technique

Tempering Technique

Characteristics 1. Air cooling hardened hot work tool steel, most widely used hot work tool steel. 2. High toughness and cold and heat-fatigue resistance. 3. Excellent toughness hot fatigue resistance and certain abrasion resistance at medium temperature. 4. During air cooling, deformation and oxide skin tendency is small. Good resistance from the undermining of fusing aluminum.

Delivery condition Annealing, hardness is below 235HB Surface: black, machined, painted and other customized. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Related Products : |

|

|

|

|

||||||||

|

|

|

|

stainless steel

stainless steel