|

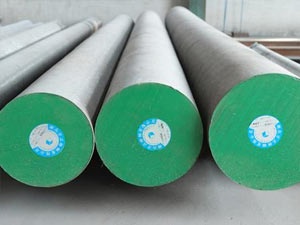

Round bar D3 steel

|

|

1.Specifications of d3 steel:

|

|

Round bar

|

Diameter(mm)

|

Length (mm)

|

|

|

10~410

|

3000~5800

|

|

|

Plate

|

Thickness(mm)

|

Width (mm)

|

Length (mm)

|

|

Max:25-200mm

|

50-610mm

|

2000~4000

|

|

The size can be customed!

|

|

2.Equivalent grade:

|

|

AISI/ASTM

|

GB

|

DIN

|

JIS

|

BS EN ISO

|

|

D3

|

Cr12

|

1.208

|

SKD1

|

X210Cr12

|

|

3.Chemical composition(%) of d3 steel:

|

|

C

|

Si

|

Mn

|

Cr

|

S

|

P

|

|

2.00-2.30

|

≤0.40

|

≤0.40

|

11.50-13.00

|

≤0.03

|

≤0.03

|

|

4.Heat treatment:

|

|

Isothermal annealing:

- Heat to 850°Chold for 1/2 hour to 1 hour;

- Furnace cooling to 770°C and hold at temperature for at least 10 hours;

-Cool by 10°C /h to 720°C;

-Cooling in air.

|

|

Stress relieving:

To be carried out after machining and before the final heat treatment.

-Heat to 650-700°C, hold for 4/6 hours:

-Furnace cooling to 330-350°C;

-Cooling in air.

|

|

Hardening:

-Initial preheating to 350-450°C;

-Second preheating to 750-850°Cin salt bath at 850°C;

-Austenitizing at 960-100°C;

-Cooling in fluid oil.

|

|

Tempering hardness: 64-65 HRC

|

|

5.Application:

|

|

1.Steel with wear resistance and fairly good dimensional stability during heat treatment.

|

|

2.Rolls for cold strip mills and wire squeezer mills, circular knives and shear blades.

|

|

3.Dies for small metal parts, punches and drawing dies, dies for sintering, forming tool rollers, shear blades.

|

|

4.Molds for plastic materials. Statically and dynamically stressed components for vehicles,engines and

machines.

|

|

5.For parts of larger cross-sections,crankshafts,gears,wear-resisting press tool and guide palte.ect.

|

|

6.Characteristic:

|

|

1.Very high resistance against abrasive and adhesive wear due to a high volume of hard carbidesin the steel.

|

|

2.Matrix moderate machinability good dimensional stability

|

|

3.Toughness and through hardenability

|

|

7.Machinability

|

|

The machinability rating of D3 is roughly 25 % that of free machining carbon steel 1018.

Due to its abrasion resistant nature, machining in the hardened condition should be limited to finish grinding.

|

|

8.Inspection:

|

| 100% Ultrasonic according to the test standards:SEP1921-84,GR.3 CLASS C/C or by SGS ,AHK or Alex Stewart |

stainless steel

stainless steel